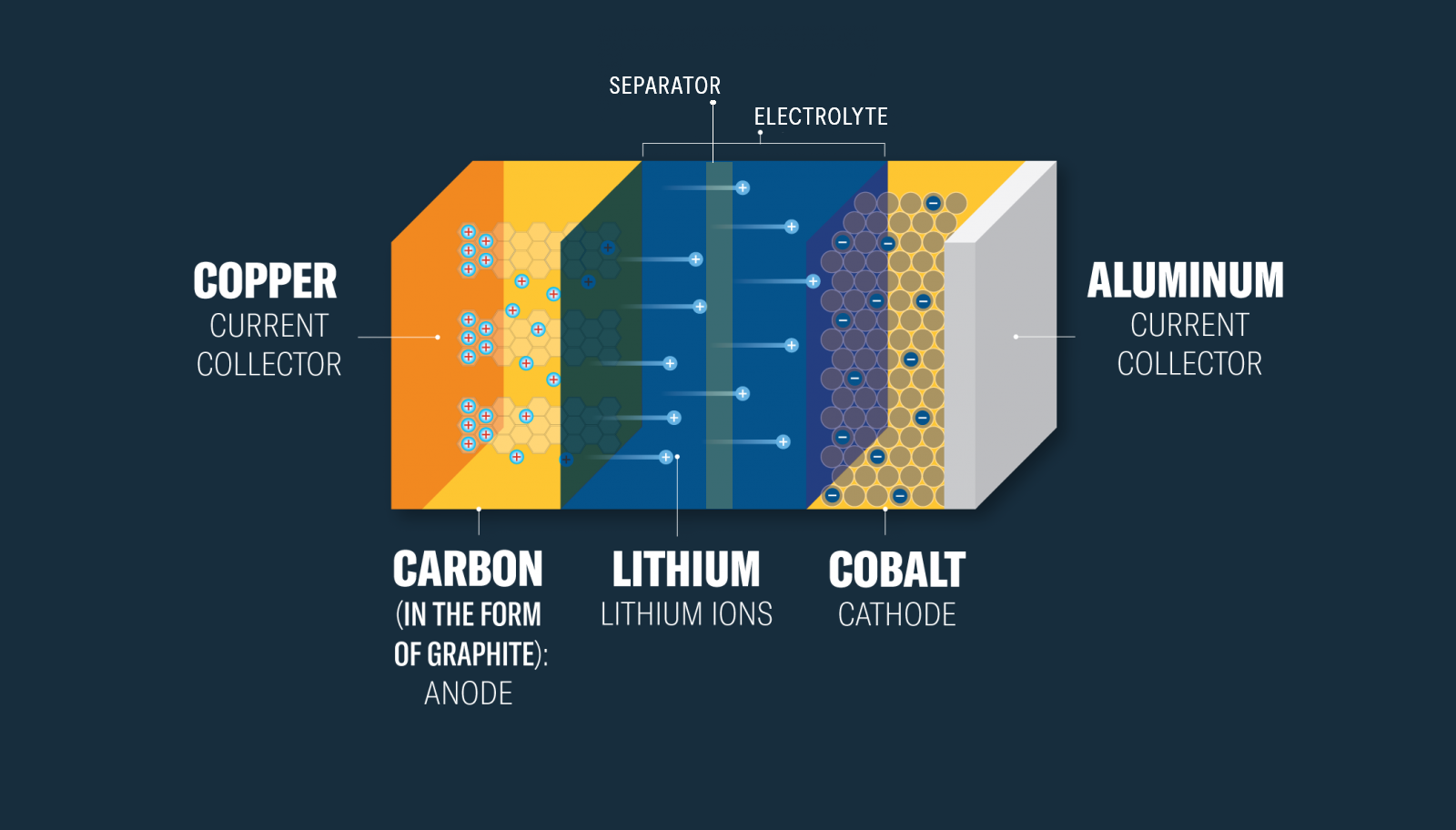

Five of the important elements to a lithium-ion battery are cobalt, copper, lithium, aluminum, and carbon in the form of graphite.

- What do you notice about the organization of the components in the battery model?

- What do you notice about the way the elements are positioned to make a battery work?

- What does this model make you wonder about the way a battery is made? Or the way a battery works?

- Based on each resource’s properties, why do you think they are important to a lithium-ion battery? Use the periodic table to note properties of these elements. Which are metals? Which are non-metals?